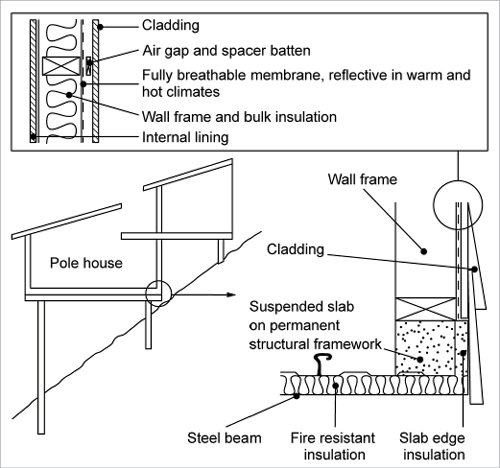

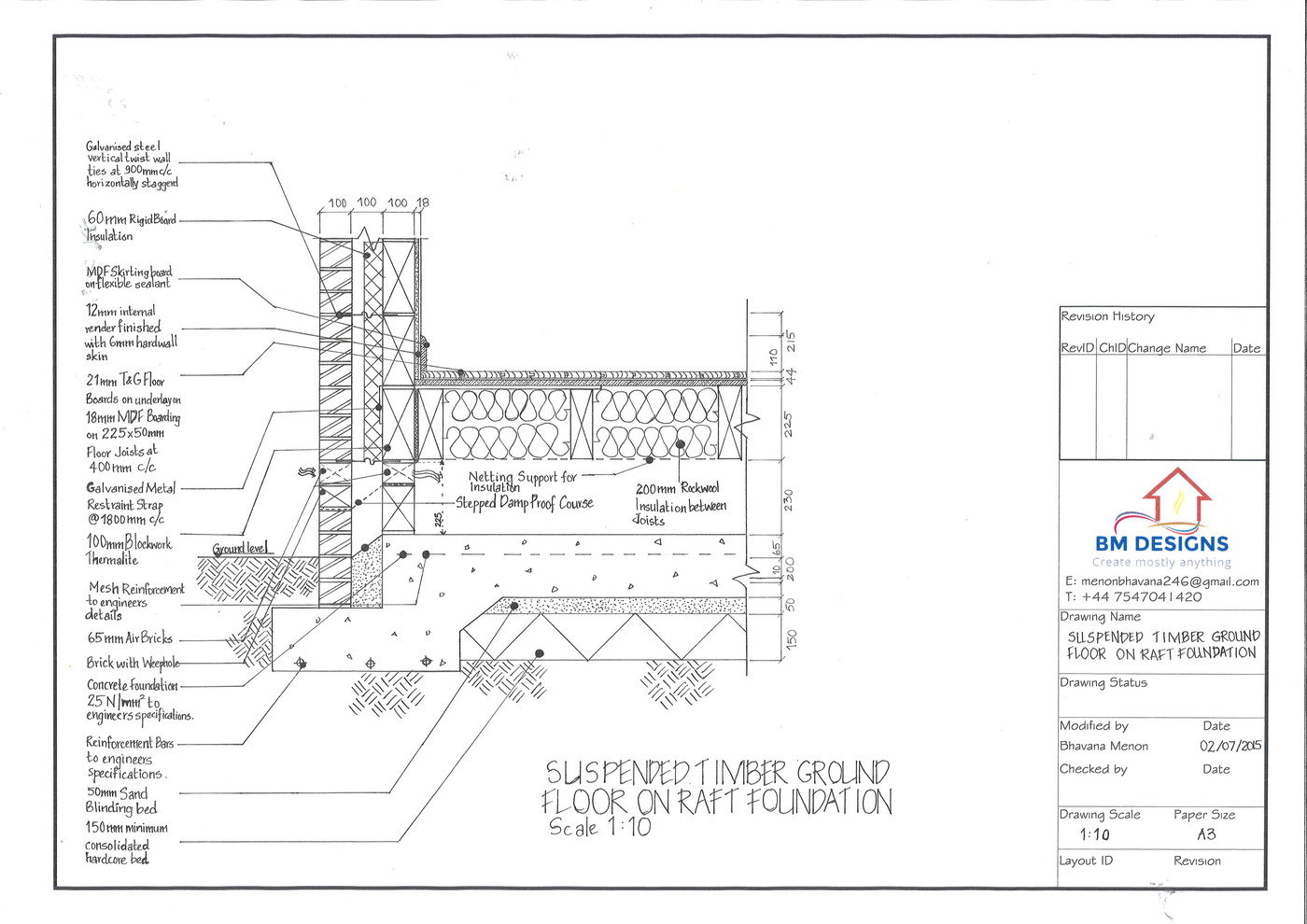

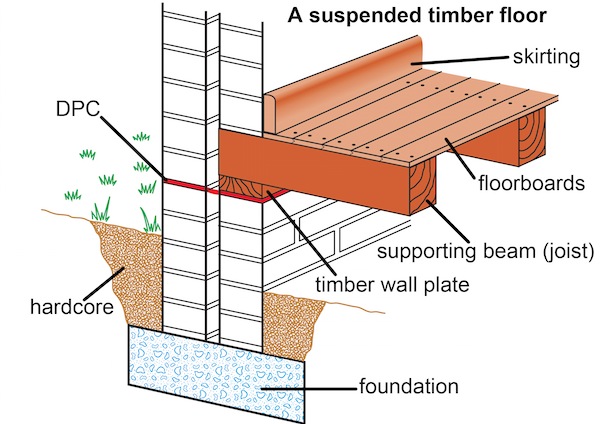

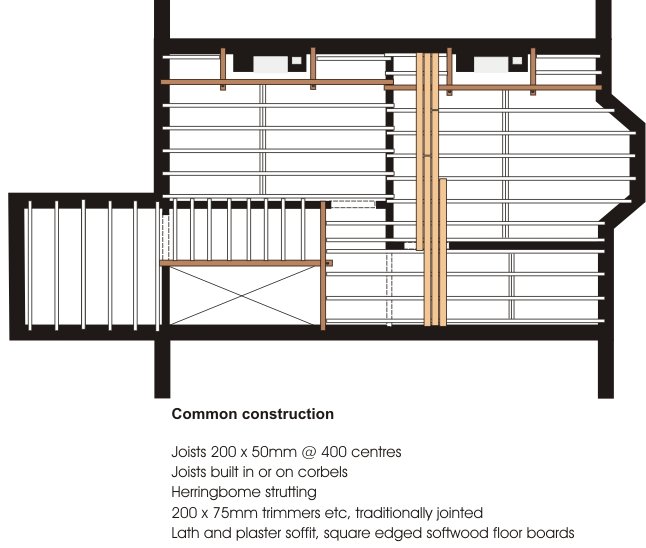

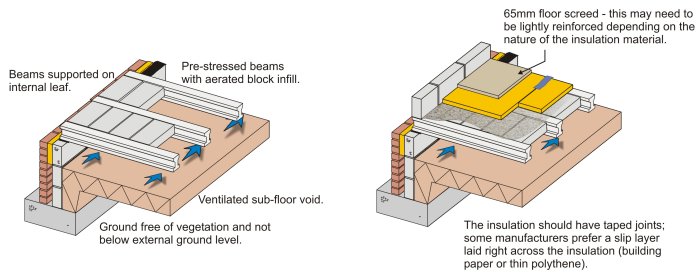

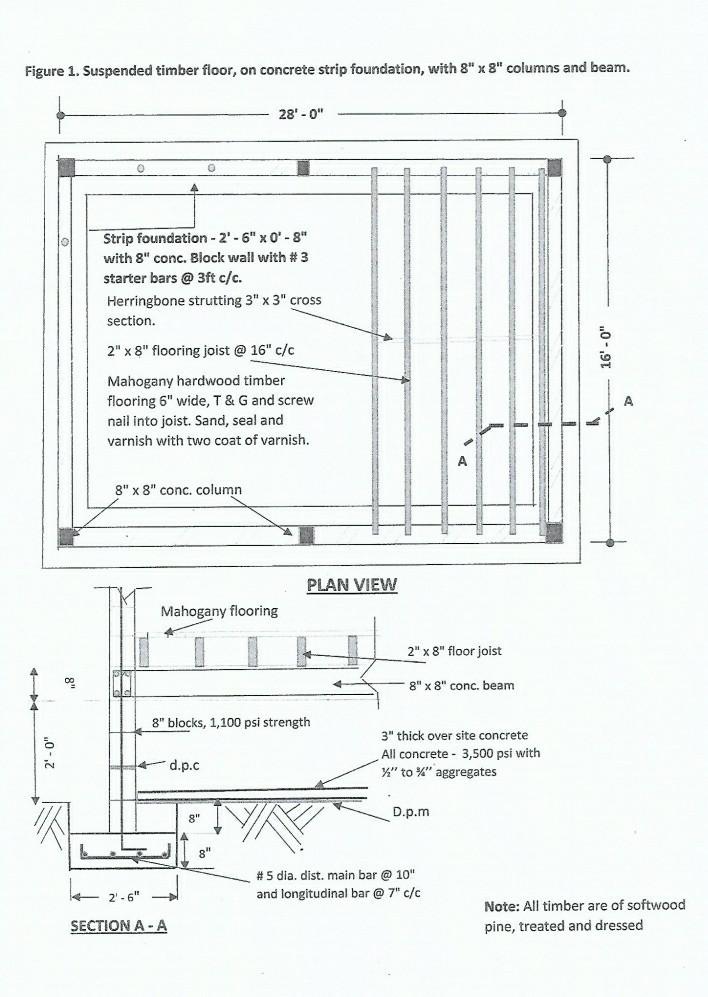

Note The Detail Drawings are applicable to work in England & Wales only A suspended timber floor with the flooring lifted to expose the sleeper walls Image courtesy of myretrofitblogspotcom Suspended, hollow or timber floors also have a tendency to creak as the nails work loose over time The answer to this problem can also be found in our project aboutThis chapter gives guidance on meeting the Technical Requirements for suspended ground floors including those constructed from insitu concrete precast concrete timber joists 521 Compliance 522 Provision of information 523 ContaminantsThe constructional details from the bottom of the foundation to 400mm above finished floor level and include the abutment of both floors (For the purposes of this drawing, show a minimum 15 metres width for each floor type) (b) Indicate on the drawing a design detail to show the cross ventilation of the suspended timber floor

Concrete Slab Floors Yourhome

Suspended timber floor detail drawing

Suspended timber floor detail drawing-Wood Floor Detail Drawing Solid wood floors over concrete slabs hardwood sports floor systems wood floor framing details detail tech solid hertog Traditional Technical Architectural Detail Drawing By E Hall Scientific Diagram Laminate Flooring Laminaat Wood Png 00x1162px Adhesive Diagram Do It Yourself DrawingOne Hz equals one cycle per second

Suspended Timber Floor Detailed Drawing Youtube

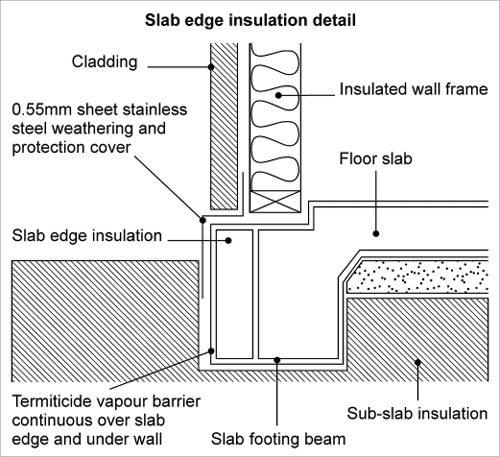

A Best Practice Approach To Insulating Suspended Timber Floors Fintan from our Technical Team discusses the thermal loss issues associated with suspended timber floors and outlines a best practice approach to tackling them At the turn of the 18th century, when construction techniques moved from boarded floors installed directly on the groundNHBC requires ground floors to be constructed as suspended floors in the following situations where the depth of fill exceeds 600mm, as described in Chapter 51 'Substructure and ground bearing floors' (Design) where soil swelling may occur, as described in Chapter 42 'Building near trees' on sites which have been subject to vibratory ground Since a large number of different floor finishes are designed for use on screeded floors, we will look at all of these, including timber products, in the next section Here we're going to talk about traditional suspended timber floors The timber floor structure will be shown in detail on the plans and drawings

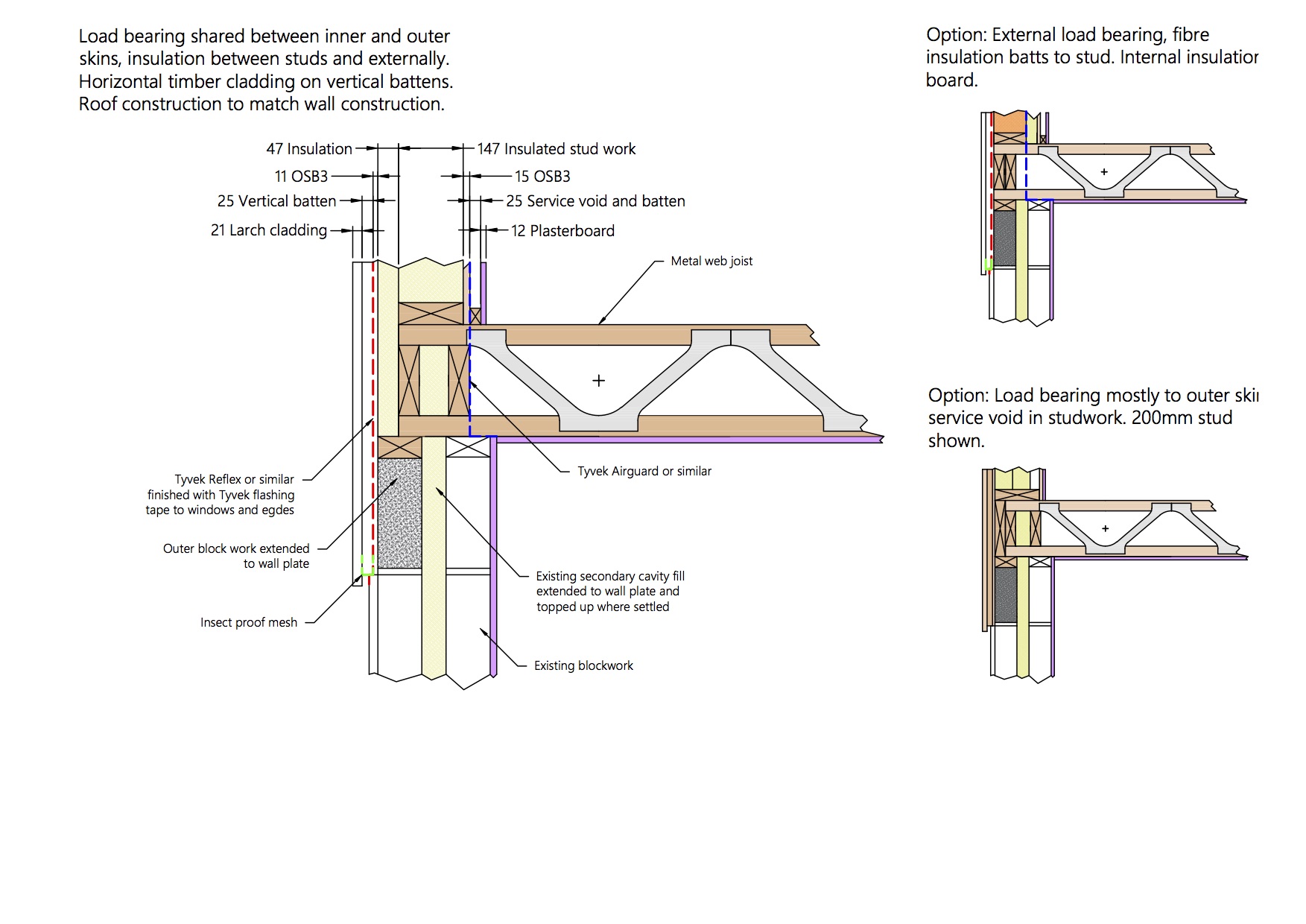

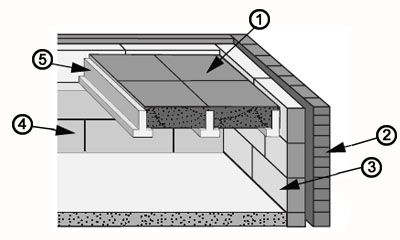

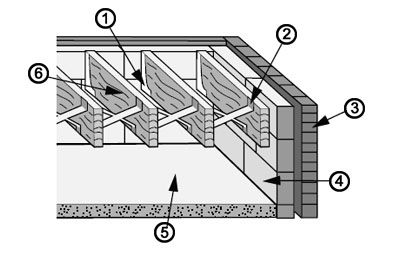

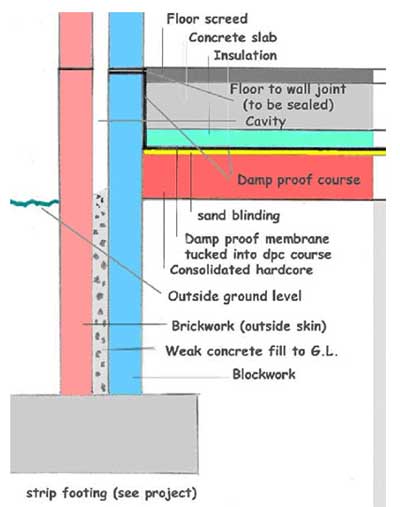

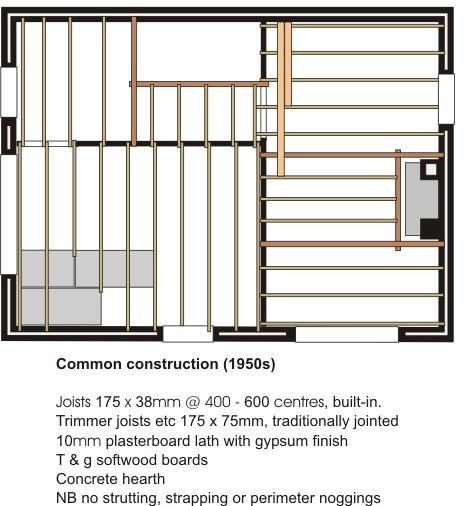

Construction Detail Drawing Passive Concrete Cavity Wall with an Insulated Suspended Timber Floor Key skills needed for Mandatory Exam Paper Question 1!!!Solid floors are a lot more substantial and require the ground to be made up in layers of ground sub base, sand, compacted hard core, damp proof membrane, insulation and concrete Suspended floors are normally made up of 2 materials, either timber joists or a concrete beam system There are quite a lot of variations on these types of floor, mainly depending on what use you intend forFloor / Ceiling 1Hour 3" x 111/2" F/D joists @16" OC, Span 15', live load 60lbs, 1 layer 2" x 8" T&G, 1 layer wood flooring WFC118 Wood Floor / Ceiling 1Hour 3" x 8" joists @145 oc, span 24', live load 40lbs, 2 layers 3/4" wood

Precautions • Soil below timber floor – covered with PCC 124 (100 to 150 mm thk) • DPC – exterior wall top of the sleeper wall • Well seasoned timber is used • Hollow space between bottom of concrete and floor level is filled up with selected earth 6 S i n g l e j o i s t t i m b e r f l o o rs 2 c Joist Span (below 3m A suspended timber ground floor needs decent subfloor ventilation to outside air and you need to make sure the sub floor area is well sealed from the room above The Celotex suggested is ideal for this, with a generous application of expanding foam inSuspended Timber Floor Suspended Timber Floor Specific applications Specific applications CAD Drawings HY – Sectional Detail HY02 Window – head detail HY03 Window – Sill details HY04 Window – Jamb detail HY05 Wall – Ground floor detail HY06 Wall – intermediate Floor detail HY07 Wall – Separating floor detail

Http Isobioproject Com Wp Content Uploads 19 01 Isobio Nb Guide Warm Passivhaus V 2 Pdf

Build A Dry Risk Free Finished Basement Fine Homebuilding

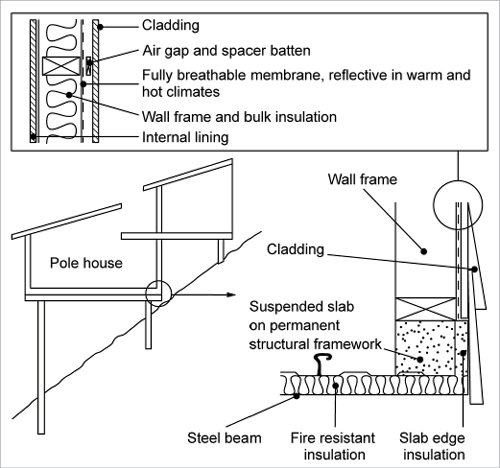

Floor structures are generally one of two types – solid or suspended Suspended timber floors, which are typically found in older houses, are normally made from timber floorboards which are then attached to joists just above the foundations of a house This creates a small gap and allows ventilation and air movement to prevent damp forming inTIMBER FRAME STANDARD DETAILS SEPTEMBER 09 Building 1 Grosvenor Court, Hipley Street Air Leakage Details 91 Floor Junction 92 Internal to External Wall Junction 103 Floor Assembly 104 Sheet materials on joists 105 Temporary bracing Silvatec Design Ltd Timber Frame Design and Structural Engineers Silvatec Levels Ltd Suppliers Timber deck finish can also be used – if this is specified a vapour control layer must be included in the design under the timber deck A void is left under the floor of at least 150mm between the soil and underside of the beam If heavy clay soil is present it is good practice to increase the void depth to as much as 225mm or possibly more

The Different Types Of Suspended Wooden Flooring Construction

How To Get Better At Architectural Detailing 101 First In Architecture

I hope you enjoyed the journey as we took 13 working days to build this one from demolition to finish #drdecks #yourprescriptionforquality regalideas timbertech mascore_helical_piles chrisflynn6 cutek_extreme cuthub metabohpt diamondbacktoolbeltsA selection of floor detail drawings including block and beam floors, timber suspended floors, solid ground floors and upgrade floor details Drawings are directly downloadable in Jpeg (1600 by 10px), DXF and DWG (cad) formats Note The Detail Drawings are applicable to work in England & Wales onlySuspended timber floor construction Saved by UN Food & Agriculture Organization 5 Timber Flooring Wood Construction Plywood Projects To Try Floor Plans Teaching Architecture Wood Flooring Hardwood Plywood

Www Scoilnet Ie Uploads Resources 246 Pdf

What Is A Suspended Timber Floor Discount Flooring Depot Blog

#09 • Timber Flooring Design Guide Page 6 1 Timber Flooring and Floor Finishes 11 Movement in Timber Floors Prior to discussing timber flooring products, it is important to understand the relationship between timber, humidity in the air surrounding it and the dimensional changes that occur as the result of changes in humidity A suspended floor is a ground floor with a void underneath the structure The floor can be formed in various ways, using timber joists, precast concrete panels, block and beam system or cast insitu with reinforced concrete However, the floor structure is supported by external and internal walls Supports underneath the floor are permanent and include sleeperDownload this free CAD drawing of suspended wooden floor details for use in construction design CAD drawings Today Explore When the autocomplete results are available, use the up and down arrows to review and Enter to select Touch device users can explore by touch or with swipe gestures

Sub Floor Perimeter Insulation Vented Shallow Suspended Floor Retrofit Pattern Book

Suspended Timber Floor Construction Timber Flooring Roof Construction Timber

Well over 5 years later and I am back at it!I love these clean and minimal lines and I feel we delivered just that on this awesome #deck!A polished timber floor looks warm and inviting, but looks can be deceiving If you've got a suspended timber floor which is not insulated, it can contribute to

Gallery Of Holm Place Ob Architecture 35

Technical Detailing By Bhavana Menon At Coroflot Com

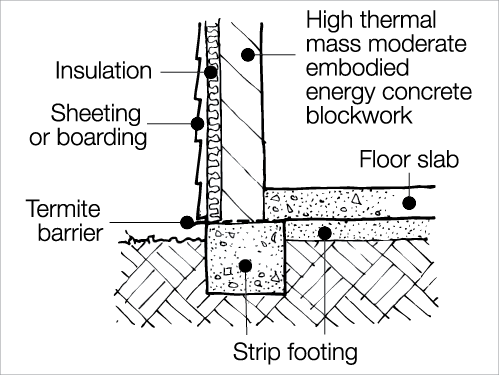

Beam and joist floor frames can be constructed on site or off site and transported in, depending on your foundation The wood is water and weatherproofed first, and may be termite proofed as well when needed The beams are laid down, grooves are cut in and the joists are then fitted in Joists should only ever meet each other over the middleFloor bearers are an idea introduced by some shed companies to really minimise the material cost of the sheds they produce The timber size is generally very small often 2x1" or sometimes less The bearer needs to have an almost continuous or very frequent support The support could be a level concrete base or possibly a timber subfloorDownloadable detail drawing showing an internal partition to suspended floor detail in timber frame construction 15 scale at A3 size, PDF format For use in a Building Regulations application or as a general construction detail The following is guidance from the Planning Portal about making a Full Plans Application This internal partition

What Is A Suspended Timber Floor Discount Flooring Depot Blog

Building A Timber Frame First Floor Over A Cavity Wall Timber Frame Buildhub Org Uk

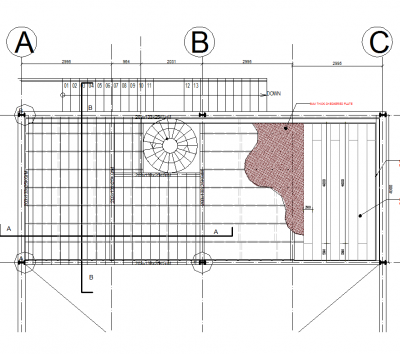

Figure 1 Suspended timber floor joist layout (redrawn from NZS Figure 72) Figure 2 Lateral support offset from brace line (redrawn from NZS Figure 610) Figure 3 Packers between doubled joists under loadbearing wallsA suspended timber floor with the flooring lifted to expose the sleeper walls – Image courtesy of myretrofitblogspotcom Suspended, hollow or timber floors also have a tendency to creak as the nails work loose over time The answer to this problem can also be found in our project about stopping creaking floors and stairsProposed 3rd Floor Timber Floor Typical BuildUp Location 3F Typical Floor Buildup Details E/CON002 15 @ A1 JK B 005m01m 02m 03m 04m 05m SCALE 1 5 SCALE 1 1 0m 0m 10mm mm 40mm 60mm 80mm 100mm TENDER DATE GENERAL NOTES THIS DRAWING IS TO BE READ IN CONJUNCTION WITH ALL OTHER OSEL TENDER/CONSTRUCTION

Construction Studies Student Wood Theory Practice

Foundation Walls Branz Renovate

Construction Studies drawing detail of suspended timber floorFor most situations where internal floor areas are greater than 600mm below external ground level, additional protection may be required Therefore, these drawings are for general guidance only, and further advice should be sought when necessary from our Technical team Phone 9440 or Email technical@riwcoukFirst steps Adding Strip, Wall and Hardcore Adding Radon and Subfloor Adding Tassel Wall and Wall Plate

Suspended Floors All You Need To Know Thermohouse

Suspended Timber Upper Floor Components

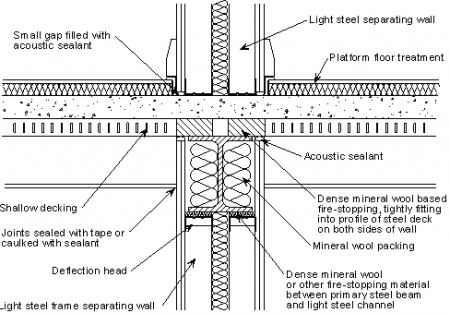

All beam and block flooring systems must have appropriate thirdparty certification The manufacturer's details and specification for the floor must include • Structural calculations for the floor indicating depth and centres of the precast floor beams • The minimum specification of walls supporting the beam and block floorThe details contained in this document are intended as a general guide for using Steel Stud Manufacturers Association (SSMA) member products These products should not be used in design or construction without an independent evaluation by aPitch The oscillation rate of a sound wave, which travels as a small pressure change alternating above and below the static (at rest) state of the conducting material Each cycle of compression and reexpansion is a wave The number of waves occurring per second is the frequency, which is measured as hertz (Hz);

Part 1 Technology 3 Folio

Fbe 03 Building Construction Science Lecture 3 Floor

It applies to suspended timber floors located above an unheated space, where the insulation is installed below the floorboards or timber decking timber floors situated above an unheated integralA selection of floor detail drawings including block and beam floors, timber suspended floors, solid ground floors and upgradeDrawings However, there are exceptions and the actual construction of partition attachment in a seismic design category can meet code requirements in different ways Partition extending from floor to structure Partition attached to suspended ceiling partition partition suspended ceiling structure partition partition suspended ceiling structureCeiling joists are usually 2 by 6s or sometimes 2 by 4s if it is an older home Some newer homes have manufactured, I beam–shaped joists Floor joists, spaced on regular

Sportengland Production Files S3 Eu West 2 Amazonaws Com S3fs Public Floors For Indoor Sports Pdf

Http Www Foresitebuildingcontrol Com Pdfview Aspx Filename Pf 7 4c

Different types of ground floor suspended flooring Suspended timber floors need to have spaces underneath ventilated via air 'bricks' through the outer walls and gaps in any internal walls so that the air can move across the building underneath the floors to prevent the build up of moisture in the timber which could lead to fungal attack A suspended timber floor is constructed as a timber platform of boards nailed across timber joists supported on sleeper walls, and the external and internal load bearing walls surrounding them Ventilation must be provided throughout the underfloor void and through any sleeper walls with cross ventilationSuspended Ceilings PH 14S Construction Details Timber Floors & Roofs T E C H N I C A L D A T A 1 PROMATECT®H boards, thickness commensurate with fire resistance performance required 4 2 Ceiling channel section 50mm x 27mm x 06mm to form grid at 610mm x 12mm spacing 3 Mild steel angle 50mm x 30mm x 06mm thick 4 M4 selftapping screws at nominal 0mm centres 5

Building Regulations 4 Plans Construction Detail Drawings

Suspended Timber Floor Detailed Drawing Youtube

Sheathing, usually tying the ends of floor trusses together (Also referred to as a Ribbon or Band Board) Rise Vertical distance from bottom most part of the bottom chord to inside of the peak Scab Additional timber connected to a truss to effect a splice, extension or general reinforcement Shop DrawingDetailed drawings of a roof There are some useful drawings that show how suspended timber floors should be built Bearing details for suspended timber floors on ground level A competent person (civil engineering) shall design and inspect fills where the maximum height of fill beneath floors, measured at any point, exceeds 400 mm A floor's framework is made up mostly of wooden joists that run parallel to one another at regular intervals Floor joists are typically 2 by 8s, 2 by 10s, or 2 by 12s;

Flexural Strengthening Of Old Timber Floors With Laminated Carbon Fiber Reinforced Polymers Journal Of Composites For Construction Vol 21 No 1

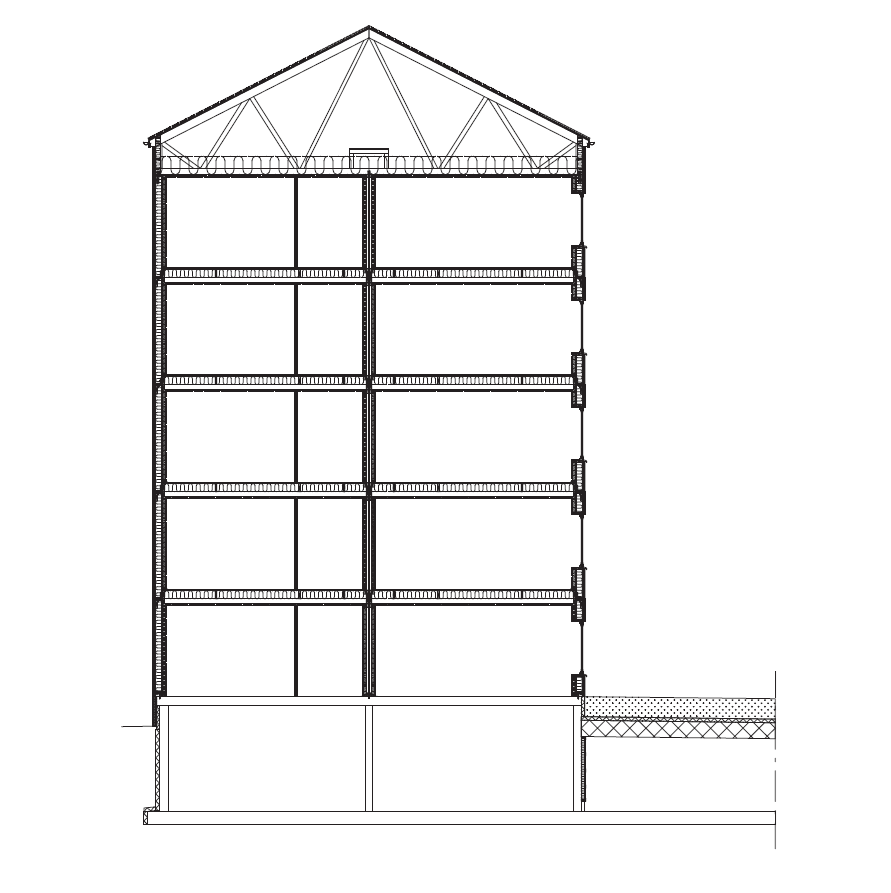

Floor Systems Steelconstruction Info

6410 Construction of timber floors Upper floors shall be constructed in a workmanlike manner and provide satisfactory performance Issues to be taken into account include levelling joist spacing and clearance support312 Timber Frame – Timber suspended ground floor 313 Timber Frame – Separating wall (junction with external wall) 314 Timber Frame – Timber separating floor 315 Timber Frame – Intermediate floor / external wall 316 Timber Frame – Ground floor / separating wall junction – timber suspended floorSuspended Timber Floors are constructed using floor joists to support the implied loads on the floor The joist can be of a traditional solid timer or a rationalised engineered joist that is more environmentally friendly and may have been manufactured from recycled materials In most applications where underfloor heating is used

Www Scoilnet Ie Uploads Resources 248 Pdf

Suspended Floors All You Need To Know Thermohouse

Additional Construction Details Drawings As well as the small selection of foundation, wall, floor and roof construction detail drawings shown here, many of the Building Notes have a related Construction Detail Drawing, with specific dimensions eg rafter sizes, spans, insulations types, for purchase with the Building Specifications©TIMBER QUEENSLAND LIMITED TECHNICAL DATA SHEET 18 TIMBER FLOORS RECOMMENDED INSTALLATION Revised March 14 Page 1 The ground beneath a suspended floor should also be graded so that no ponding is possible Where springs or aquifers Refer Figure 2 for details FLOOR LAYING PRACTICES The moisture content, size and profile of the

Technical Detailing By Bhavana Menon At Coroflot Com

Building Guidelines Concrete Floors Slabs

Beam And Block Floor With Render Walls Detail Drawing

Floor Detail Drawings

Pdf Three New Design Tools For Residential Concrete Masonry Construction In New Zealand Semantic Scholar

How To Choose A Floor Structure Homebuilding

Suspended Timber Floor Construction Studies Q1

Fastrackcad Cad Details

Suspended Floor Underfloor Heating Suspended Floor Heating

Ground Floor Ventilation To Insulated Floor Retrofit Pattern Book

Door Threshold Construction Studies Q1

Timber Construction Systems Swedish Wood

The Different Types Of Suspended Wooden Flooring Construction

Conservatories Online Suspended Timber Floor Detail

Constructing A Suspended Floor To Building Regs Youtube

The Different Types Of Suspended Wooden Flooring Construction

Www Rbkc Gov Uk Idoxwam Doc Drawing Pdf Extension Pdf Id Location Volume2 Contenttype Application Pdf Pagecount 1

Floor Construction Detail Detailed Drawings Concrete Blocks Detail

Floor Framing Structure

Concrete Slab Floors Yourhome

Www Diynot Com Diy Attachments Suspended Timber Floor Pdf

1

Internal Partition To Suspended Floor Detail Drawing

Woodfloor With Labels S Sans Building Regulations South Africa

Timber Construction Floor Google Search Construction Details Architecture Floor Insulation Timber Flooring

Timber Suspended Floating Floor System Using R10

Eurima Suspended Timber Floors

A Layout And Dimensions Of The Field 2 4 W Timber Floor B Download Scientific Diagram

Survey Sketches My Cms

Suspended Ground Floors Suspended Timber Floor 800x400 Png Download Pngkit

Evolution Of Building Elements

Detail Post Floor Details First In Architecture

Floor Detail Drawings

Building Guidelines Drawings Section B Concrete Construction

Www Aivc Org Sites Default Files Airbase 107 Pdf

Building Guidelines Drawings Section B Concrete Construction

1

Www Scoilnet Ie Uploads Resources 248 Pdf

How To Choose A Floor Structure Homebuilding

Top Schematic Drawing Of The Detailing Between Masonry Ground Floor Download Scientific Diagram

Concrete Floors And Replacing A Timber Floor With Concrete After Dry Rot Diy Doctor

Floors Dctech

Www Ukradon Org Cms Assets Gfx Content Resource 2732cs Pdf

Raised Floor F175 Knauf Gips Kg Cad Dwg Architectural Details Archispace

Thermal Mass Yourhome

3

Approved Document C Free Online Version In 21 Timber Flooring Flat Roof Extension Floor Insulation

Detail Post Floor Details First In Architecture

Suspended Timber Floor Construction Studies Q1

Http Www Hyne Com Au Documents Feature documents Tq 18 Timber Floors Recommended Installation Final Pdf

Concrete Slab Floors Yourhome

Pin On Ae

Gymnasium On Suspended Wood Floor Structural Engineering General Discussion Eng Tips

Thermoblock A Simple Solution To Thermal Bridging From Marmox

Building Guidelines Suspended Timber Floors

Evolution Of Building Elements

Concrete Vs Timber Floors

Http Www Hyne Com Au Documents Feature documents Tq 18 Timber Floors Recommended Installation Final Pdf

Evolution Of Building Elements

Timber Floor

Suspended Wooden Floor Cad Details Cadblocksfree Cad Blocks Free

Www Aivc Org Sites Default Files Airbase 107 Pdf

Week 9

Diagram Of Suspended Timber Floor With Underfloor Heating Pipes Underfloor Heating Floor Heating Systems Hydronic Radiant Floor Heating

Assignment Iii Instruction Answer The Following Chegg Com

Detail At Floor External Door Junction

Suspended Timber Floor Detailed Drawing Youtube

Raised Floor F175 Knauf Gips Kg Cad Dwg Architectural Details Archispace

Concrete Vs Timber Floors

6 Ground Floors Construction Studies

Underfloor Heating For Joisted Timber Floors Warmafloor Esi Building Services

Detail Post Floor Details First In Architecture

Insulating Suspended Wooden Floors Wooden Flooring Underfloor Insulation Flooring

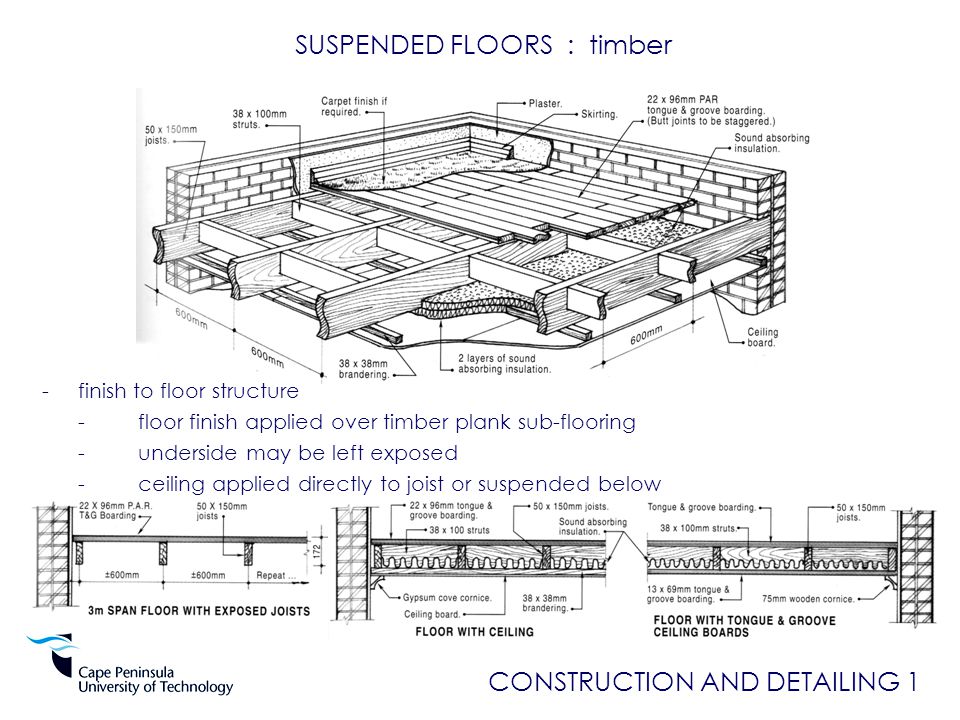

Construction And Detailing 1 Ppt Video Online Download

Should You Replace Your Old Timber Floor With A Concrete Floor Dampchat

Suspended Timber Floor By Bpptech Issuu

Suspended Timber Floor Construction Studies Q1

Roof Wall Or Floor Insulation Design Guidance From The Expertsballytherm Co Uk